We have developed the MAM Perfect soother with a patented extra-thin and flexible teat for more natural mouth closure to reduce the risk of misaligned teeth and support a healthy dental development for your baby.

MAM Perfect Soother Benefits

Our MAM Perfect unique teat shape is 60% thinner and 4x more flexible than comparable soother teats.¹ This extra-thin soother teat allows your baby to close the mouth in a more natural position, enabling a more natural tongue position, which is important for speech development.

MAM Perfect Soother age ranges

At MAM, we believe in providing the best care for your baby at every stage of their development. That's why the MAM Perfect soother is available in different sizes, ensuring a perfect support throughout your baby’s dental development.

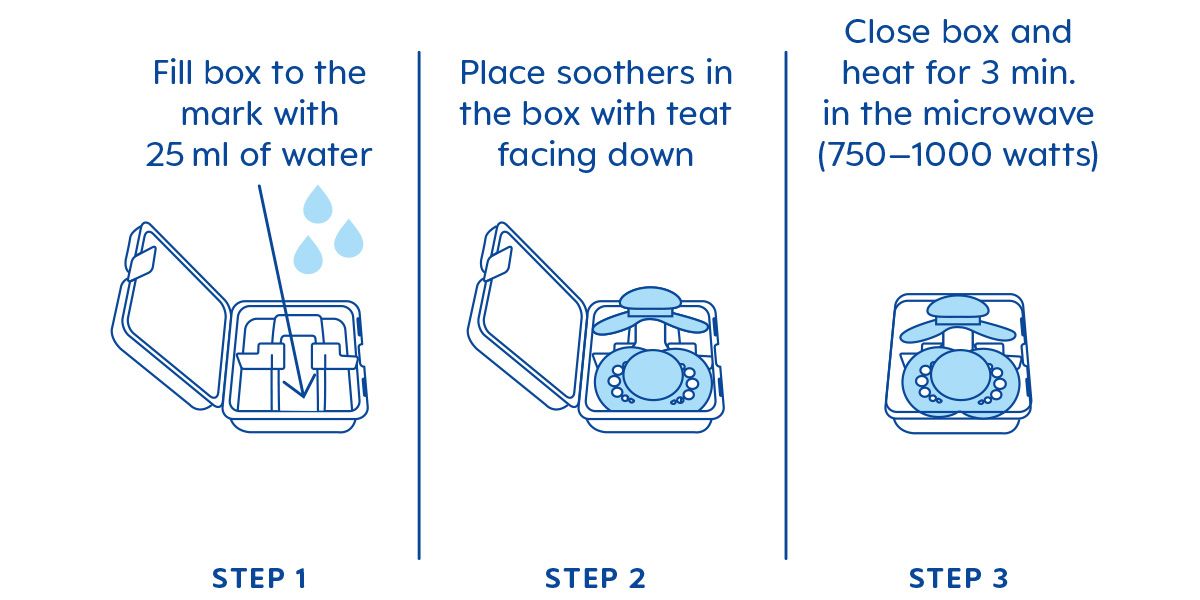

How to sterilise a soother?

The MAM Perfect soother is packed in a soother steriliser box that is a handy carrying case and lets you sterilise your soothers in a few simple steps. The sterilising function of this box enables to disinfect soothers hygienically and quickly in the microwave in an energy-saving process. Using the steriliser box saves up to 77% of energy and CO². 4

Sterilised in 3 minutes – for up to 48 hours:

- Fill box with water to the 25ml mark

- Place soother in the box with the holder

- Close box and heat in microwave for 3 minutes at 750-1000 watts

Sustainability at MAM

Sources:

1.) Scientific reports from Wild Hi-Precision institute verify that the MAM Perfect’s teat neck is on average 60% thinner. A series of tests by the University Clinic of Dentistry Vienna confirm that it is also on average 4 times more flexible than comparable pacifiers. (Between: 32-83% thinner and 1.1-19.5 times more flexible than regular silicone pacifiers).

2.) Y. Wagner, R. Heinrich-Weltzien, “Effect of a thin-neck pacifier on primary dentition: a randomized controlled trial”, Orthodontics & Craniofacial Research, Volume 19, Issue 3, pages 127–136, August 2016

3.) Market research 2010-2022, tested with 1,541 babies.

4.) Global Product Carbon Footprint Study, Austria 2013, conducted by denkstatt.

5.) Based on the ISCC PLUS certified mass balance approach, bio-circular raw materials can be traced back to vegetable oils as well as waste and residues from the production of plant-based oils.